Biodegradable Vegan Leather

Najina Persimmon Leather

Limitations and Issues of Conventional Leather

Why do we need a new leather?

Issues of Natural Leather

Environmental Pollution & Animal Sacrifice

Production Process Issues

- ・Generation of massive wastewater and by-products

- ・Use of various hazardous substances including trivalent chromium

- ・Inevitable animal sacrifice (criticized by animal welfare organizations)

Disposal Issues

- ・Emission of hazardous substances during incineration → Air pollution

- ・Soil contamination during landfill

- ・Environmental hormone risks (phthalate plasticizers, organotin)

Issues of Synthetic Leather (PU/PVC)

Non-biodegradable & Chemical Substances

Environmental Destruction

- ・100% non-biodegradable

- ・Generation of microplastics

- ・Emission of toxic gases during incineration

Harmfulness

- ・Contains phthalate plasticizers

- ・Detection of organotin compounds

- ・Potential human health hazards

Issues of Conventional Vegan Leather

Limitations of Pineapple, Mushroom, Cactus, and Grape Leather

Non-biodegradable

- ・Plant-based fibers + PU coating

- ・Plant-based protein + PU mixed coating

- ・Use of chemical coating agents and binders

- → Eventually 100% non-biodegradable

High Cost

- ・Complex manufacturing process

- ・Expensive raw materials and technology

Unresolved Environmental Issues

- ・Difficult to recycle

- ・Greater environmental burden during disposal

What Makes Najina Persimmon Leather Special

5 Core Values

100% Plant-based Leather

True plant-based leather made by converting persimmons into plant-based resin and coating it on natural fabric (Persimmon Vegan Leather)

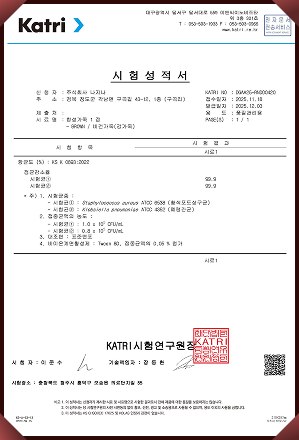

Natural Functionality

Possesses natural functionalities inherent in persimmon tannin, including antibacterial and deodorizing properties

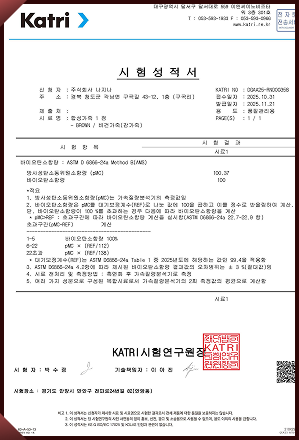

Truly Biodegradable

90.8% biodegradation in just 45 days, completely solving recycling and environmental issues

Clean Manufacturing Process

Dramatically minimizes chemicals and wastewater in the manufacturing process, reducing environmental pollution and practicing animal welfare and carbon neutrality

Reasonable Price

50% cheaper than conventional vegan leather, solving even recycling and disposal issues

Preserving the Unique Feel of Leather

2 Color Options

Different from Conventional Leather

What Makes Najina Persimmon Leather Special

Deodorizing 99%

UV Protection

Najina Persimmon Leather

Deodorizing 99%

UV Protection

How is Persimmon

Leather Made?

Clean & Efficient Manufacturing with Minimized Process Steps

3-Step Eco-friendly Process

STEP 1

Persimmon Dyeing of Fabric

(Tannin Pretreatment)

- ・Imparting antibacterial and deodorizing functions

- ・Enhancing plant-based resin adhesion

- ・Fabric stabilization and shrinkage prevention

STEP 2

Persimmon Tannin Processing

& Plant-based Resin Production

- ・Persimmon tannin extraction and concentration

- ・Combination with plant-based protein

- ・100% natural resin formulation

STEP 3

Plant-based Resin Treatment

(Leather Production)

- ・Direct coating method

- ・Zero Water Usage (No Wastewater)

- ・Roll-unit production

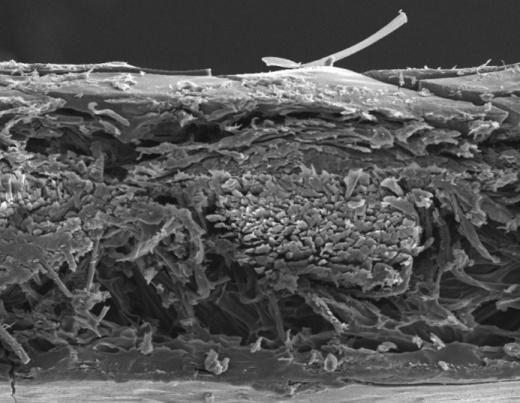

Biodegradable

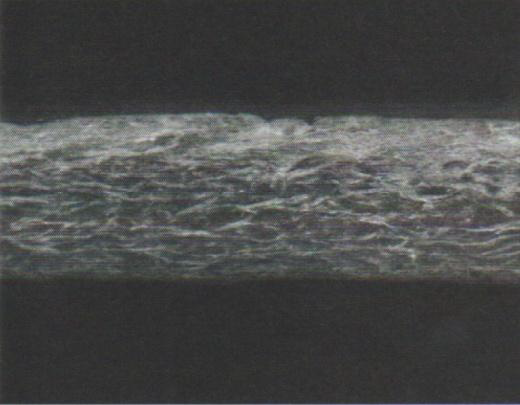

Cross-section of Persimmon Leather

Natural Functionality

Herbal medicine, natural materials, etc.

(Antibacterial & Deodorizing Functions)

Natural Fabric

"Vegan Leather"

Product Cross-section Comparison

Coating Layer Similar to Natural Leather

Najina products can adjust the total thickness according to fabric selection and surface coating layer thickness.

Natural Leather

- Resin layer thickness less than 0.15mm, too thin, resulting in reduced durability

Cause of

cracking or

peeling over time

Synthetic Leather

- Non-woven fabric + synthetic resin coating

- Resin layer thickness over half

Persimmon Leather

- Base fabric structure maintained

- Persimmon resin penetrates into fabric interior

- Durability and flexibility

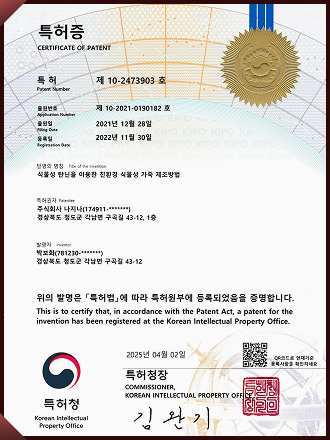

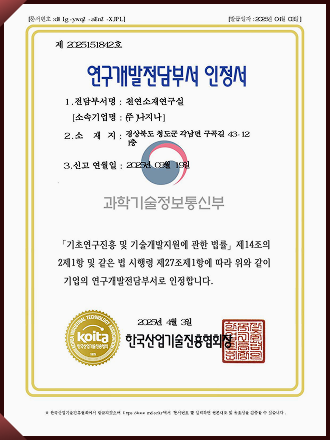

Patents & Certifications

Officially Certified Najina